Barite Introduction

Barite is a natural mineral, a sulfate mineral of barium. Its main component is barium sulfate (BaSO4). It is a non-metallic mineral product with a Mohs hardness of 3-3.5 and a specific gravity of about 4.5.

Barite is mainly formed in sedimentary environments, such as hydrothermal gangue, sedimentary rocks and mineral deposits in caves. Generally, pure barite is white and has a glassy luster. Due to the influence of impurities or mixtures, it often appears light red, gray, light yellow, etc. Good barite can also present transparent crystals, often in the form of thick plate-like orthorhombic crystals.

Barite is widely used in many fields because of its high density, stable chemical properties, and non-toxic and non-magnetic characteristics.

Uses of Barite

Petroleum industry: Barite is an important catalyst. In oil well drilling, barite powder above 200 mesh is used as a weighting agent for circulating mud to help the stability of the drilling process.

Plastic industry: barite can be used as a filler for plastic raw materials, making the color of the product more beautiful and rich, while also improving the rigidity, strength and wear resistance of the product. Such as plastic basins, plastic buckets, etc.

Rubber industry: barite powder is also a filler for rubber products, which not only improves the hardness, water resistance, acid and alkali resistance of the product, but also reduces the production cost. Such as rubber tubes, rubber seals, etc.

Infrastructure industry: barite is a commonly used building material, mainly used as paving materials, concrete aggregates, cement, gypsum, etc., which not only improves the wear resistance and hardness of the product, but also can adjust the performance of the product. Such as buried pipes, replacing lead plates for nuclear facilities, and extending the life of the road surface.

Paint coatings: barite replaces titanium dioxide, lead powder, precipitated barium sulfate and other high-priced raw materials, and is used as a filler for coatings and paints, which can not only control the viscosity of the paint, but also make the product stable and brighter in color. Such as furniture paints, wall coatings, etc.

Glass industry: barite can be used as a clarifier, flux, etc., which can enhance the optical stability, strength and gloss of glass. Such as glass curtain walls of buildings.

Ceramic industry: barite is also an excellent filler in the ceramic industry. Ceramic products with barite are not only of good quality, but also have improved appearance.

Papermaking industry: High-fineness barite powder can be used for coating fillers, copperplate paper fillers, etc. to improve whiteness and surface coverage.

Metal manufacturing: barite has corrosion resistance and expansion properties. It is used in the manufacture of magnesium alloys, aluminum, titanium, etc. to improve the corrosion resistance and strength of products.

Smelting industry: barite can also be used as a flux for iron ore to improve production efficiency and reduce production costs.

Barite grinding production

Equipment required for production

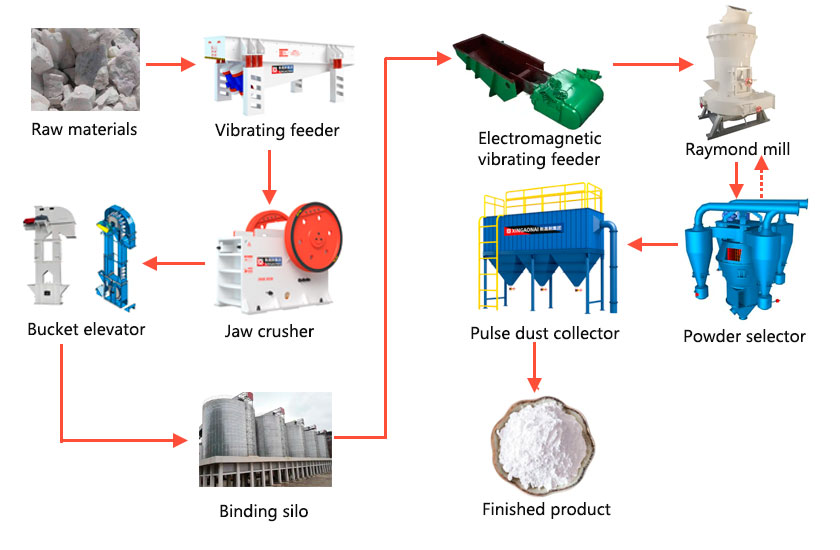

Including vibrating feeder, jaw crusher, bucket elevator, electromagnetic vibrating feeder, Raymond mill, powder selector, pulse dust collector, belt conveyor, etc. We can choose the appropriate type and model of production equipment according to the material conditions and production requirements.

Barite grinding production process

Crushing: The vibrating feeder evenly feeds the large pieces of barite raw materials into the jaw crusher for primary crushing, and then the crushed barite raw materials are evenly fed into the silo by the bucket elevator.

Grinding: The barite materials in the silo are evenly fed into the Raymond mill by the electromagnetic vibrating feeder for grinding, and the grinding reaches the required mesh size.

Powder selection: The barite powder that meets the requirements is sent to the powder selection machine for classification, and the unreasonable fine powder is sent back to the Raymond mill for grinding.

Collection: The qualified barite powder is collected through the pipeline device and finally sent to the silo for packaging.(xingaonai)

Comments on “The use of barite and the production process of grinding”